Sunday, 16 July 2017

Sunday, 7 May 2017

Wednesday, 26 April 2017

Hydraulic system

Hydraulic system : Mohammad

moklas

28.04.2017

A hydraulic driven drive framework is a drive or transmission

framework that utilizations pressurized pressure driven liquid to control water

powered hardware. The term hydrostatic alludes to the exchange of vitality from

stream and weight, not from the dynamic vitality of the stream.

Pressure driven machines are hardware and apparatuses that

utilization fluid liquid energy to do basic work. Substantial gear is a typical

case. In this kind of machine ,water driven liquid is transmitted all through

the machine to different pressure driven engines and water powered barrels and

progresses toward becoming pressurized by the resistance display.

these are the customary parts of repositories; new patterns

may introduce deviations from the standard. For instance, new plans for water

powered frameworks regularly call for stores that are considerably littler than

those in view of customary general guidelines. Since most frameworks warrant

some unique thought, it is essential to counsel industry models for least rules.

Hydraulic pump types

Fixed displacement types.

- Gear Pumps. Probably the simplest and most common used

today, they are easily maintained and economic. ...

- Gerotor Pumps.

- Screw Pumps.

Variable displacement types.

- Bent Axis hydraulic pumps.

- Axial Piston Pumps.

- Radial Piston Pumps.

Three main types of hydraulic pumps

are used in the fluid power industry. They are vane pumps, gear pumps and

piston pumps, all of which are types of positive

displacement pumps. Essentially, this means that they transfer a measured

quantity of pressurized hydraulic fluid into a hydraulic system.

Gear Pumps

Rigging are a kind of Rotary Positive

Displacement Pump. They comprise of no less than two discrete and turning gears

with intermeshing teeth. As these fit teeth discrete, they make an incomplete

vacuum which is filled by the liquid being pumped.

A rigging pump produces stream via

conveying liquid in the middle of the teeth of two lattice gears. One apparatus

is driven by the drive shaft and turns the idler rigging. The chambers framed

between nearby apparatus teeth are encased by the pump lodging and side plates

(likewise called wear or weight plates).

Gerotor

Gerotor is a positive relocation pump

The name gerotor is gotten from "Created Rotor". A gerotor unit

comprises of an inward and external rotor, with the external rotor having n+1

teeth with n characterized as a characteristic number more prominent than 2.

The hub of the internal rotor is counterbalanced from the pivot of the external

rotor and both rotors turn on their particular tomahawks. The geometry of the

two rotors segments the volume between them into n diverse powerfully evolving

volumes. Amid the get together's turn cycle, each of these volumes changes

constantly, so any given volume initially increments, and after that

abatements. An expansion makes a vacuum This vacuum makes suction, and thus,

this piece of the cycle is the place the admission is found. As a volume orders

pressure happens. Amid this pressure period, liquid can be pumped, or compacted

(in the event that they are vaporous liquids).

Gerotor pumps are for the most part

planned utilizing an inward rotor and an external rotor framed by a hover with

crossing roundabout arcs.

A gerotor can likewise work as a guns

High weight gas enters the admission zone and pushes against the internal and

external rotors, making both turn as the region between the inward and external

rotor increments. Amid the pressure time frame, the fumes is pumped out.

Screw Pumps.

Ascrew pump is a positive-displacement

(PD) pump that use one or several screws to move fluids or solids along the

screw(s) axis. In its simplest form (the Archimedes' screw pump), a single

screw rotates in a cylindrical cavity, thereby moving the material along the

screw's spindle.

Bent

Axis hydraulic pumps

Bent axis fixed displacement axial

piston pumps for open circuit applications are designed for operation in

systems typified by heavy duty work cycles. Closed circuit axial piston motors

are used mainly for rotary drives in power machinery or in hydrostatic

transmissions. Fixed displacement motors can also be used in open circuit applications,

and are therefore suitable for a variety of hydraulic circuits

Axial

Piston Pumps

A hub cylinder pump is a positive

uprooting pump that has various pistonsin a roundabout cluster inside a barrel

square. It can be utilized as a remain solitary pump, a water powered engine or

a car aerating and cooling compressor.

Radial Piston Pumps.

A spiral cylinder pump is a type of

water driven pump. The working cylinders stretch out in an outspread course

symmetrically around the drive shaft, rather than the pivotal cylinder pump.

Monday, 24 April 2017

Solenoid Valve Tutorial tips

Solenoid Valve Tutorial Tips: moklas

Solenoid valve definition:

A solenoid valve is an

electromechanically worked valve. The valve is controlled by an electric

current through a solenoid: on account of a two-port valve the stream is turned

on or off; on account of a three-port valve, the surge is exchanged between the

two outlet ports .A solenoid valve is an electromechanical controlled valve.

The valve includes a solenoid, which is an electric loop with a portable

ferromagnetic center in its middle. This center is known as the plunger. In rest

position, the plunger shuts off a little hole. An electric current through the

loop makes an attractive field. The attractive field applies a drive on the

plunger. Therefore, the plunger is pulled toward the focal point of the curl so

that the hole opens. This is the essential rule that is utilized to open and

close solenoid valves. "A solenoid valve is an electromechanical impelled

valve to control the stream of fluids and gases

Circuit

Functions Of Solenoid Valves

Solenoid

valves are utilized to close, measurements, disperse or blend the stream of gas

or fluid in a pipe. The particular reason for a solenoid valve is communicated

by its circuit work. A 2/2 way valve has two ports (delta and outlet) and two

positions (open or shut). A 2/2 way valve can be 'regularly shut' (shut in

de-invigorated state) or 'ordinarily open' (open in de-empowered state). A 3/2

way valve has three ports and two positions and can along these lines switch

between two circuits. 3/2 way valves can have distinctive capacities, for

example, regularly shut, typically open, redirecting or all inclusive. More

ports or mixes of valves in a solitary development are conceivable. The circuit

capacity can be communicated in an image. The following are a few cases of the

most well-known circuit capacities. The circuit capacity of a valve is

symbolized in two rectangular boxes for the de-empowered state (right side,

envisioned by ) and invigorated state (left). The bolts in the case demonstrate

the stream heading between the valve ports. The illustrations demonstrate a

2/2-way Normally Open (NO) valve, 2/2-way Normally Closed (NC) valve and a

3/2-way Normally Closed valve. For more data about valve images and circuit

capacities,

Direct Operated

Solenoid

valve have the most basic working standard. The medium moves through a little

opening which can be stopped by a plunger with an elastic gasket on the base. A

little spring holds the plunger down to close the valve. The plunger is made of

a ferromagnetic material. An electric loop is situated around the plunger. When

the loop is electrical empowered, an attractive field is made which pulls the

plunger up towards the focal point of the curl. This opens the hole so that the

medium can course through. This is known as a Normally Closed (NC) valve. A

Normally Open (NO) valve works the inverse way: it has an alternate development

so that the hole is open when the solenoid is not fueled. At the point when the

solenoid is impelled, the hole will be shut. The greatest working weight and

the stream rate are straightforwardly identified with the hole distance across

and the attractive drive of the solenoid valve. This standard is in this way

utilized for generally little stream rates. Coordinate worked solenoid valves

require no base working weight or weight contrast, so they can be utilized from

0 bar up to the greatest permissible weight. The showed solenoid valve is a

direct worked, typically shut 2/2 way valve.

Indirect

Operated (Servo Or Pilot Operated)

(additionally

called servo worked, or pilot worked) utilize the differential weight of the

medium over the valve ports to open and close. Generally these valves require a

base weight differential of around 0.5 bar. The channel and outlet are isolated

by an elastic film, likewise called stomach. The film has a little opening so

that the medium can stream to the upper compartment. The weight and supporting

spring over the layer will guarantee that the valve stays shut. The chamber

over the layer is associated by a little channel to the low weight port. This

association is hindered in the shut position by a solenoid. The breadth of this

"pilot" hole is bigger than the distance across of the gap in the

layer. At the point when the solenoid is stimulated, the pilot hole is opened,

which makes the weight over the layer drop. On account of the weight contrast

on both sides of the film, the layer will be lifted and the medium can spill

out of bay port to outlet port. The additional weight chamber over the layer

demonstrations like a speaker, so with a little solenoid still a huge stream

rate can be controlled. Aberrant solenoid valves can be utilized just for one

stream heading. Aberrant worked solenoid valves are utilized as a part of uses

with an adequate weight differential and a high coveted stream rate, such as

water system frameworks, showers or auto wash frameworks. Aberrant valves are

otherwise called servo controlled valves.

Semi-Direct Operated

Semi

coordinate worked join the properties of immediate and roundabout valves. This

enables them to work from zero bar, yet at the same time they can deal with a

high stream rate. They look to some degree like backhanded valves and

furthermore include a portable film with a little hole and weight chambers on

both sides. The distinction is that the solenoid plunger is straightforwardly

associated with the film. At the point when the plunger is lifted, it

specifically lifts the layer to open the valve. In the meantime, a moment hole

is opened by the plunger that has a marginally bigger measurement than the

primary hole in the layer. This causes the weight in the chamber over the film

to drop. Thus, the layer is lifted by the plunger, as well as by the weight

distinction. This mix brings about a valve that works from zero bar, and can

control generally expansive stream rates. Frequently, semi-coordinate worked

valves have more effective curls than backhanded worked valves. Semi-coordinate

worked valves are once in a while called helped lift solenoid valves.

Direct Operated 3/2 Way Solenoid Valves

A 3/2 way solenoid valve has three ports and two

exchanging states. In each exchanging state, two of the three ports are

associated. By initiating the solenoid, the valve switches state and an alternate

association between the valve ports is set up. The drawing beneath demonstrates

a direct worked 3/2 way valve. In the de-invigorated express, the medium can

stream between from the port on the correct side to the top port. In the

empowered express, the medium can spill out of the left port to the correct

port. This is a called a typically shut 3/2-way valve.

Sunday, 23 April 2017

Friday, 21 April 2017

Sensor Tips

Sensor

Tips moklas

Give us a chance to consider

an estimation framework. It is made out of an information gadget which detects the earth or

encompassing to create a yield and, a flag preparing square which forms the

flag from info gadget and a yield gadget which displays the flag to human or

machine administrator in a more clear and usable form.The beginning stage is info

gadget which is principally what we will talk about in this part.

A sensor is a gadget that reacts to any change in physical wonders or natural factors like warmth, weight, moistness, development and so on. This change influences the physical, synthetic or electromagnetic properties of the sensors which is additionally prepared to a more usable and coherent frame. Sensor is the heart of an estimation framework. It is the main component that interacts with ecological factors to create a

yield.

All sensors should be adjusted concerning some reference esteem or standard for precise estimation. The following is the figure of a thermocouple.Note that a transducer and a sensor are not the same. In the above given case of thermocouple. The thermocouple goes about as a transducer yet the extra circuits or segments required like the voltmeter, a show and so on together from a temperature sensor. Thus the transducer will simply change over the vitality starting with one shape then onto the next and all the rest of the work is finished by the extra circuits associated. This entire gadget shapes a sensor. Sensors and transducers are firmly identified with each other.

Qualities of Sensors

A

decent sensor ought to have the accompanying qualities

High

Sensitivity: Sensitivity shows how much the yield of the gadget changes with

unit change in info (amount to be measured). For instance the voltage of a

temperature sensor changes by 1mV for each 1oC change in temperature than the

affectability of the sensor is said to be 1mV/oC.

Linearity:

The yield ought to change straightly with the info.

High

Resolution: Resolution is the littlest change in the information that the

gadget can recognize.

Less

Noise and Disturbance.

Less

power utilization.

Sorts

of Sensors

(1) Inductive sensor :Circuit diagram -

pressure tesduser sensor diagram:

Sensors are characterized in light of the way of amount they measure. Taking after are the sorts of sensors with couple of illustrations.

Sensor

characterization

In

view of the amount being measured

Resistance

temperature spoiler (RTD), a thermistor Thermocouple

Weight:

Bourdon tube, manometer, stomachs, weight gage

Constrain/torque:

strain gage stack cell

Speed/position:

Tachometer, encoder, LVDT

Light

Photo-diode light dependant resistor

Et

cetera.

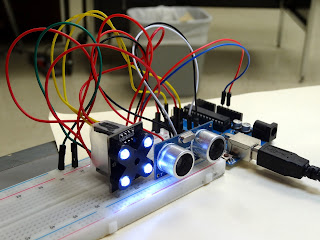

Ulrasonics sensor circuit diagram:

Ulrasonics sensor circuit diagram:

(2) Active and detached sensors: Based on power prerequisite sensors can be delegated dynamic and aloof. Dynamic sensors are those which don't require outer power hotspot for their working. They create control inside themselves to work and henceforth called as self-producing sort. The vitality for working is gotten from the amount being measured. For instance precious stone create electrical yield (charge) when subjected to increasing speed. Detached sensors require outer power hotspot for their working. The vast majority of the resistive, inductive and capacitive sensors are inactive (similarly as resistors,inductos, and capacitor are called detached gadgets).

Microsonic sensor circuit diagram:

(3) Analog and computerized sensor: A simple sensor changes over the physical amount being measured to simple shape (ceaseless in time). Thermocouple, RTD, strain gage are called simple sensors. An advanced sensor produces yield as heartbeat. Encoders are case of advanced sensors.

(4)

Inverse sensors: There are a few sensors which are equipped for detecting a

physical amount to change over it to other shape and furthermore sense the

yield flag frame to get back the amount in unique frame. For instance a

piezoelectric precious stone when subjected to vibration creates voltage. In

the meantime when a piezo precious stone is subjected to differing voltage they

start to vibrate. This property make them appropriate to use in receiver and

speakers.

Monday, 17 April 2017

Lihgt

Ligght

Prologue TO HID LIGHTING HPS :

lighting

frameworks are one of a gathering of frameworks delegated High Intensity

Discharge lighting. The HID light gathering additionally incorporates all

mercury vapor and metal halide lighting frameworks. The HID light gathering is

one of the three noteworthy light gatherings utilized as a part of present day

lighting; the others are glowing and fluorescent. To better see how HID

lighting frameworks work, a short audit of brilliant and fluorescent light

operation is useful.

Brilliant Lamps / Incandescent Lamps:

A

regular tungsten glowing light has a tungsten fiber encased in a glass globule

loaded with idle gasses (Figure 1). At the point when electric current is gone

through the fiber, it offers imperviousness to the present stream. The fiber

warms up and shines, delivering light. As the light works, the tungsten fiber

vanishes and stores as dark fixes within the globule. The dormant gasses work

to decrease this darkening, yet can't dispense with it. Light yield lessens as

the fiber dissipates, and the light inevitably flops because of fiber breakage.

Tungsten incandescent lights attempt to diminish fiber vanishing by including

little measures of bromine, constraining the tungsten to redeposit on the

fiber. Incandescent light life is about twice that of ordinary glowing lights.

Glowing lights are accessible in wattages running from 2 to 1500 watts or more.

As a rule, the light level produced by a specific luminaire can be expanded or

diminished basically by changing to various light wattage.

Fluorescent Lamps :

Fluorescent

lights are low weight or Low Intensity Discharge lights. The light comprises of

a shut tube that contains two cathodes, a latent gas, for example, argon, and a

little measure of mercury (Figure 2). At the point when voltage is provided to

the light in the right sum, an electrical curve strikes between the two

cathodes. This circular segment transmits vitality that the phosphor covering

on the light tube changes over into usable light.

Shrouded Lamps / HID Lamps:

The

HID light gathering is by a long shot the most critical light gathering

utilized as a part of present day outside and mechanical lighting. Concealed

light sources are very respected for their long life and high viability. The

minimization of HID lights additionally increments optical control and takes

into consideration a lot of adaptability in the territory of luminaire plan.

Shrouded frameworks are the most financially savvy strategy for lighting

roadways, stopping territories, sports fields, signs and structures.Concealed

frameworks additionally are in a perfect world suited for inside applications,

for example, sports fields, distribution centers, mechanical plants and certain

sorts of roundabout office and business lighting

HID OPERATION AND CONSTRUCTION All HID

:

lights

share various plan and working elements, however there are some imperative

contrasts between mercury vapor, metal halide and HPS lights (Figure 3). All

HID lights contain a fixed circular segment tube mounted inside a glass knob.

In mercury vapor and metal halide lights, the globule is loaded with hydrogen

gas, which assimilates the bright radiation delivered amid operation. HPS

lights have a vacuum inside the globule to confine the circular segment tube

from changes in surrounding temperature. As the curve tube is fabricated,

little measures of uncommon circular segment metals, for example, mercury,

halide mixes or sodium, are fixed inside the tube. Beginning gasses, for

example, argon, neon or xenon, are set inside the tube. The curve tube

additionally houses the light's two principle cathodes, in addition to the

different beginning terminal utilized as a part of mercury vapor and metal

halide lights. A HID light creates light in much an indistinguishable way from

a lightning jolt. In any case, rather than a concise glimmer, the electric

curve between the light's two principle terminals is nonstop. The striking and

keeping up of this ceaseless bend is made conceivable by the beginning gasses

and circular segment metals fixed inside the curve tube. The best possible

start-up voltage additionally is expected to build up the bend. Light start-up

is not the same for all HID

Friday, 7 April 2017

555 IC Tips

555 IC Tips

The

555 clock IC has been around now for a long while and the rundown of potential

uses for this gadget has all the earmarks of being unending. This article

contains a couple of cases of circuits that you may fuse in your next plan.

OPERATION

Before

we survey the circuits however, lets investigate the fundamental life systems

of the clock. A chart demonstrates that the circuit comprises of two

comparators, which share a typical voltage divider. Voltage got from the

divider sets two reference focuses. A low voltage, equivalent to 1/3 the supply

voltage, is connected to comparator 2 and builds up the turn on voltage, which

is anything underneath 1/3 of the supply voltage. Comparator 1 is one-sided at

2/3 the supply voltage and will react just to a flag that surpasses this level.

This empowers the 555 to work as

The

regular 8 stick DIP bundle is the most widely recognized, however a T metal can

sort is additionally accessible. Supply voltage necessities go from 3 to 18

volts, making the 555 a standout amongst the most adaptable coordinated

circuits accessible.

Another

method of operation requires just a couple milli volts to trigger the gadget on

or off, making it in a perfect world suited to touch plate circuits.

TOUCH

PLATES

A

case of a double plate controller can be found in the main circuit outline.

Resistor R1 goes about as a draw up resistor to keep stick 2 one-sided off.

Touching the on plate applies the AC voltage introduce on the surface of your

skin, to the circuit and the LED gleams. Power can be taken from stick 3 to

work a low current gadget. To kill the circuit, touch the off plate and the

power at stick three goes to zero and the LED and additionally anything

associated with stick three, kills.

A

moment touch plate configuration naturally kills after a timeframe which is

controlled by the estimation of capacitor C1 and is customizable through

potentiometer R3. This sort of circuit is appropriate for auto alerts on the

off chance that you substitute a piezo ringer for the LED.

Alerts

are exceptionally well known circuits today and the 555 clock is preferably

suited to the errand, so I would be neglectful in the event that I included no

less than one in this article. Light gives the ideal trigger source to alerts

and the circuit appeared here is among the most effortless to build.

A

cadmium sulfide photograph resistor is utilized to trigger the 555 and a

potentiometer, R2, alters affectability. Switch S1 resets the caution and a

piezo-signal fills in as the sound-delivering component.

The

majority of this and a 9-volt battery can be encased in a little venture box.

Little units like this can be utilized by an agent as a short case

alert or lodging room caution.

SCR AND

RELAY

The

555 with the utilization of SCRs or transfers can control mechanical frameworks

that require more voltage or current. A case of this sort of interface is

demonstrated the following representation. Resistor R1 gives biasing to settle

the info which is delicate to low level activating. Activating requires a

negative heartbeat and the yield remains high until the reset is locked in.

Coupling capacitor C1 passes the snappy positive heartbeat required by the SCR.

Once the SCR is turned on, it gives energy to the heap until the reset

information is activated.

On

the off chance that you have to control a substantial obligation control

source, you should seriously mull over utilizing a hand-off to substitute for

the SCR. The transfer requires a consistent DC current to stay on so the

capacitor is excluded and two diodes are utilized to avert false activating.

POSITIVE

TRIGGER

As

should be obvious, the 555 needs a negative trigger to turn on. On the off

chance that you require a positive trigger reaction, investigate the positive

trigger circuit. Resistor R1 fills in as a draw up resistor while transistor Q1

takes positive heartbeat info and presents a negative heartbeat to stick 2.